Services

What We Do

At Marathon Converting, we help you create labor and cost-saving, custom-shaped parts designed for your needs. As a tape converter, we ensure the highest quality for the adhesive solution you need to bring your products to market faster.

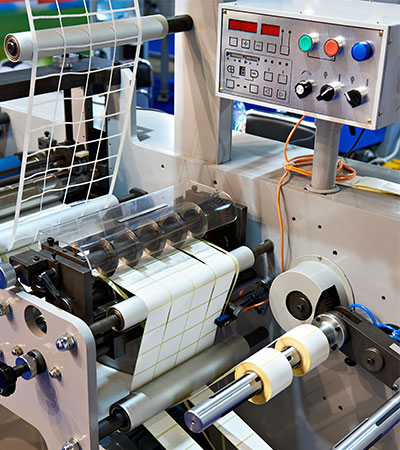

Rotary die-cutting is ideal for a wide range of projects because of the benefits it provides.

Rotary die cutting is like combining a cookie cutter with a rolling pin to efficiently create multiple and continuous shapes in a short period of time. Rotary die cutting is an efficient process for cutting a high volume of material provided in roll form.

A roll of material, or multiple rolls of different materials, is fed through a press containing a die station where a rotating cylinder blade cuts the material. The die rotates in conjunction with the material feed speed, ensuring the blades cut to exact lengths every time.

Some of the most common applications for custom die-cutting tape include: labels, decals, gaskets, nameplates, badges or emblems such as bumper stickers, decals, and vinyl wraps of virtually any form or size.

From your idea to your finished product, whether it is single or double coated tapes for industrial, electrical or medical applications, Marathon Converting will work with you to turn your ideas to reality.

Laser cutting offers many advantages as an alternative to tool-based die cutting.

Perforating

Marathon Converting’s perforating services create an easy tear line in your adhesive tape, much like sheets of toilet paper. Perforations are a sequence of holes or cuts that allow for easy tearing along the perforation. Having pre-cut pieces in a roll format makes it faster and easier for your employees or customers to apply the tape, and eliminates the need for scissors or other cutting tools.

We cut perforations to your desired length using our industry-leading equipment. Our tape perforating services are cost-effective and of the highest quality, ensuring complete satisfaction for every project.

Extended Tape Liners

Marathon Converting can add extended tape liners on your adhesive tape for easy peel-off. An extended liner has the same functionality as a pull tab, but differs in that it runs the length of the tape roll or cut to size tape strip. We commonly provide cut to size tape squares and rectangles, either in roll format or individual pieces, with a liner that is wider than the width of the tape to make it easier to handle.

Precision Tape Slitting

Precise tape slitting is a key element in producing the most excellent finished product. Utilizing innovative systems and procedures paired with advanced technology, the Marathon Converting process eliminates waste and ensures consistent and predictable results. We specialize in providing custom and narrow width slit rolls to your requirements and specifications.

Prototyping

Marathon Converting’s sheeting services provide many customers with the option of pre-cut instead of having rolls of material. Sheeting allows for individual pieces to be cut to the exact desired length instead of being wound on master roll. It provides an easy and simple way to have consistently sized, pre-cut pieces for any applications. In the standard sheeting process, we customize the length of your sheets to specifically meet your requirements.

Multiple Core Sizes

Marathon Converting can convert pressure-sensitive adhesive tapes on a variety of tape cores, offering the sizes and materials you need for your unique application. We can lathe slit and rewind tape onto 1.5-inch, 3-inch and 6-inch cores. This helps ensure the finished tape you receive is perfectly catered to your needs.

The material used to create the tape core is important for making sure the roll doesn’t collapse under the weight of the tape material. That’s why we offer both paper and plastic cores in various wall thicknesses. Regardless of your application, Marathon Converting can convert nearly any adhesive tape product and pair it with the tape core best suited for your needs.

Custom Part Fabrication

Request a Quote Today

Reach Us

Location :

19244 Airport Road, Summerstown, ON K0C 2E0

Email :

solutions @ marathonconverting.com